With the process of industrialization, the degree of factory automation is getting higher and higher, and a large number of pipelines, equipment, valves, etc. constitute the factory production system. Regular inspection of the production system to eliminate safety hazards and avoid major losses of life and property is the top priority of factory safety work. The sonic imager detects sound waves, sound fields, and sound sources to determine whether there are abnormal noises during mechanical operation and whether there are leaks in pipelines, so as to prevent safety issues caused by leaks in pipelines, pump valves, etc.

The origin of the research on the concepts of acoustic imaging and acoustic wave visualization can be traced back to the schlieren imaging method invented by German physicist Topler in 1864; that is, by adjusting the light source, the effects caused by sound waves can be seen in the originally transparent air. Air density changes.

With the development of acoustic imaging technology, acoustic imagers have developed into mic arrays that can utilize multiple highly sensitive mics. In the audible and ultrasonic frequency bands, through optimizing genetic algorithms and far-field high-resolution beam forming and other technologies, The collected sound is visualized on the screen in the form of a color contour map, so that operations such as partial discharge, equipment abnormal noise locating, and gas leak detection can be performed.

Multi-scenario applications of sonic imagers

Different from the point-to-point detection of most inspection methods, the auscultation-style inspection of sonic imagers greatly improves the efficiency of inspections. For companies with large factory areas, many risk points for gas leakage, and high pressure on inspection personnel, sonic imagers are the ideal solution. The best choice to improve the safety management level of the factory and reduce the workload of personnel.

For example: in the petrochemical industry, it can help detect air leakage problems in pipelines and valve interfaces; in the power industry, it can help troubleshoot partial discharges and mechanical failures in power facilities; in environmental monitoring, acoustic imagers can locate and provide early warning for abnormal noise ; In public transportation, illegal honking behavior and the roar of bombing street cars can be captured.

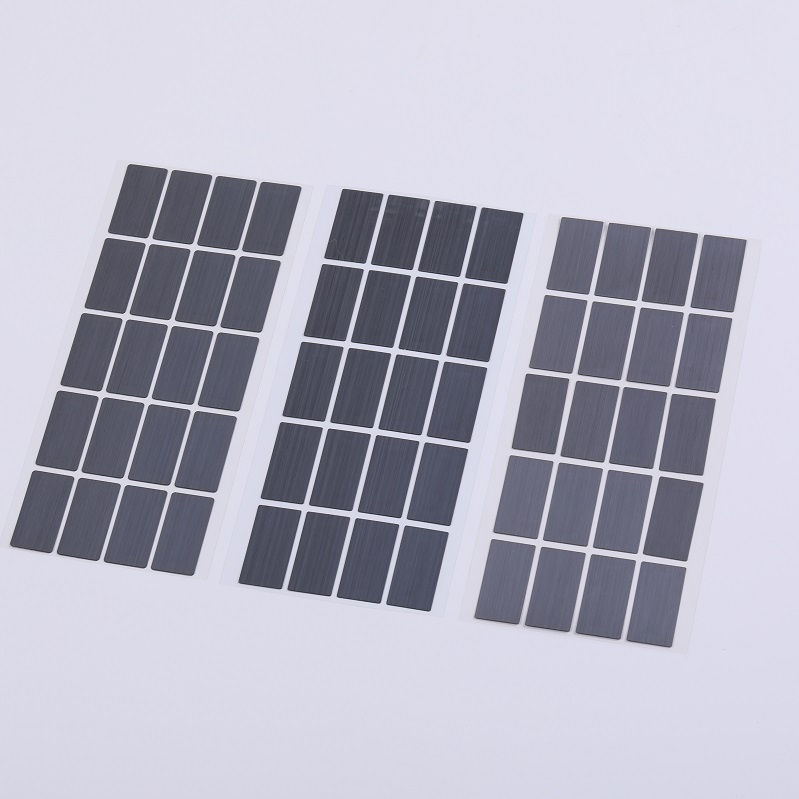

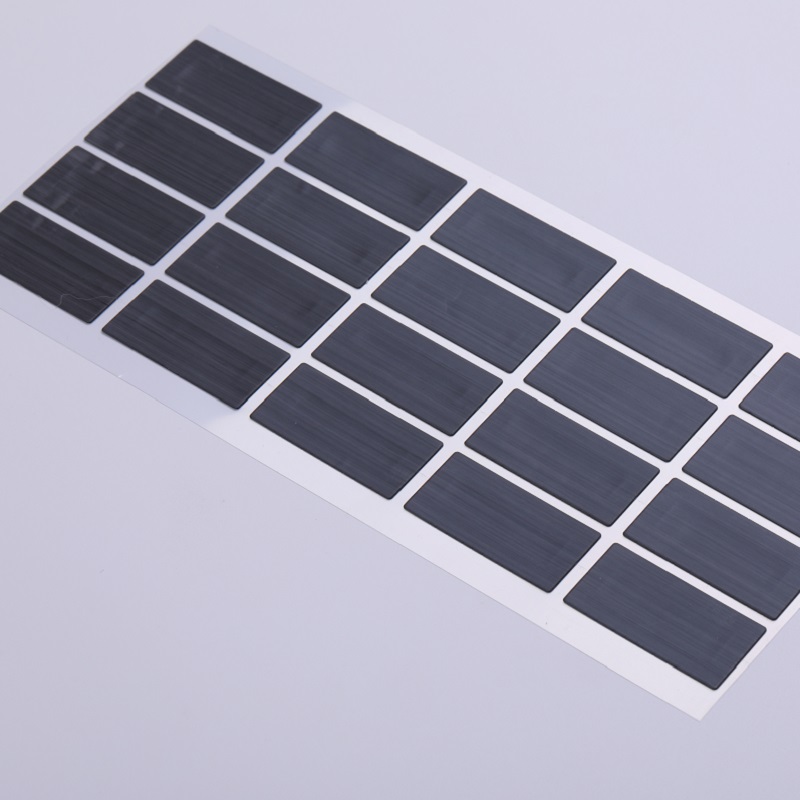

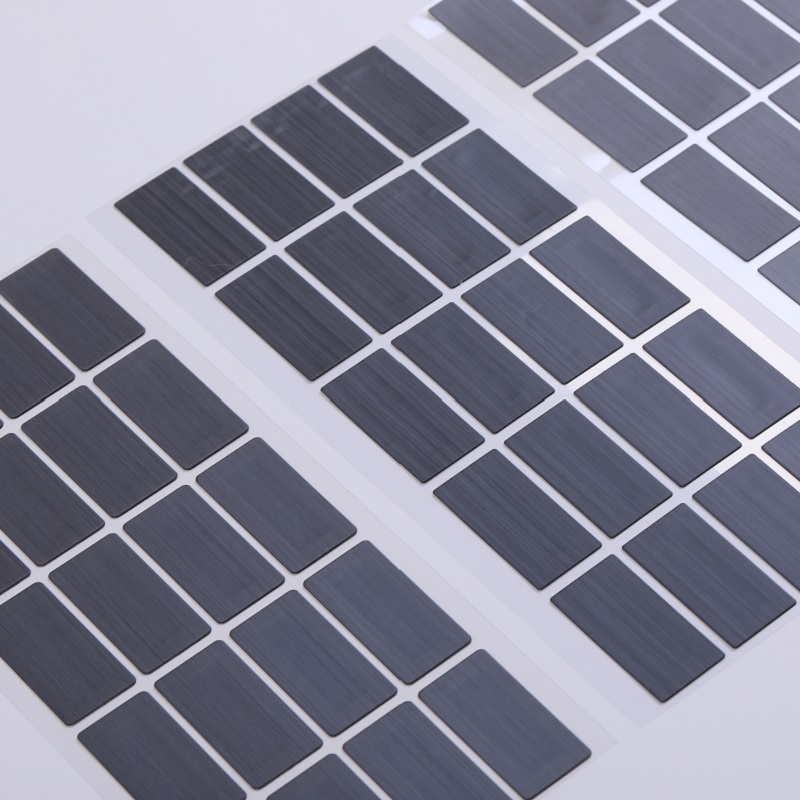

The multi-scenario application of sonic imagers places high demands on their waterproofing, dustproofing, and audio consistency. In order to support online detection in audible and ultrasonic frequency bands with high sensitivity, the acoustic imager needs to make hundreds of shell openings in one-to-one correspondence according to the number of mics on the mic array. In order to prevent rainwater and dust from entering the cavity through the opening of the shell, damaging electronic components and interfering with sound detection, it is necessary to install a waterproof sound-permeable membrane at the opening of the shell:

1. High waterproof and dustproof requirements in rainy environment

2. Low sound loss in the audible and ultrasonic frequency ranges

3. Audio consistency for hundreds of mics

Post time: Nov-16-2023